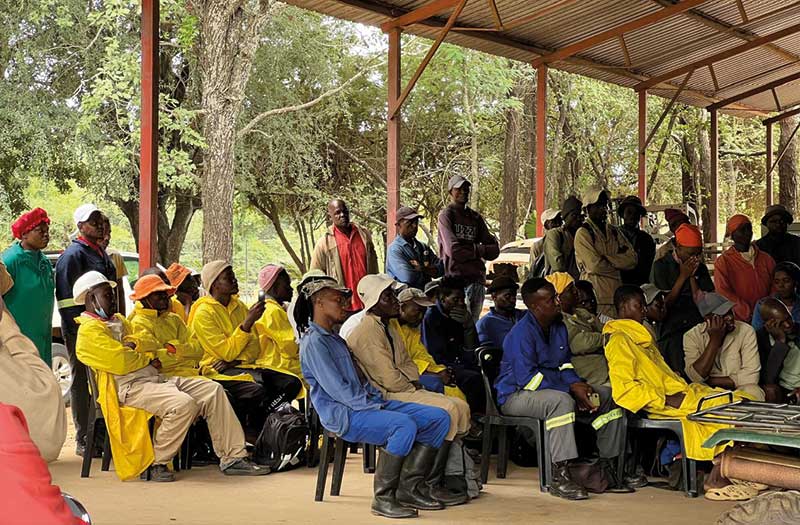

Villa agronomist Vivian Butler achieved a remarkable feat in March 2025, training 642 farm workers from 34 farms in Limpopo in the safe handling of crop protection products in March alone. This photograph was taken on a farm in Letsitele during one of these sessions. He managed these impressive numbers by arranging several training days where growers from various farms could bring workers to a central location. In 2024, he trained 915 agri workers.

“Is dishwashing liquid dangerous?”

“No.”

“And if you drink a whole bottle of it?”

Nervous laughter.

This is a regular exchange between Villa agronomist Charla Meyer and farm workers during her occupational safety training sessions on farms. “You have to take things right to the basics, even to explain the concept of what chemicals are,” she says.

Mandatory under stewardship legislation, these training sessions are aimed at explaining the risks and best practices associated with the use of crop protection products. The regulations, jointly developed by government and the industry, are designed to protect both the users of these products and the environment in which they work.

The course content was developed by industry body CropLife SA, but in adapting it for sessions that she and other Villa agronomists present, Charla has made it more visual and interactive for the benefit of those who cannot read or write. “The overall message in these sessions is that the chemistry is not the hazard, but that the way we use it will determine whether they could become a hazard or make people ill.”

The Villa agronomists take audiences through the information-rich product labels, explaining all the elements and what they mean. Many farm workers are surprised to learn of the lengthy process these products have to undergo before they can go on sale – a number of trials in different climate regions, followed by an adjudication process with the Registrar of Act 36 of 1947 that could take four years or longer.

“Then there’s the GHS system – explaining all the pictograms and the fact that it is a worldwide system so anyone using a particular product, be they here or in Taiwan, can understand the nature of the risks associated with the product, even if they cannot understand the language of the label.”

Rules have their reasons

Charla wants the workshops to empower farm workers with an understanding of why certain rules exist, rather than just telling them what the rules are. “It’s human nature – when you tell people, ‘Don’t do this; don’t do that,’ they tend not to listen. But if they appreciate there are risks involved and understand the reasons behind the rules, they see things differently.”

While producers are generally well acquainted with the risks associated with crop protection products, she believes farm workers do not always realise the enormous impact on the environment if you accidentally knock over a 20-litre container of chemicals. “It’s not just the cost of those lost chemicals; it’s what they do. It can pollute the environment; it can kill organisms, animals, maybe even children walking by. Rinsing those containers in the veld and emptying the water on soil where someone else has to walk, chickens eat or children play is dangerous.”

Instead, empty containers must be thoroughly rinsed with water three times, the water emptied in a drain, and the container perforated with a screwdriver to prevent reuse. They also talk farm workers through all the eventualities and proactive measures that need to be in place should something go wrong.

“Why do we not use wooden shelves? They absorb chemicals. Why do we need emergency numbers on the wall? Do you have emergency numbers in your work spaces? Well, then tell your supervisor it must be rectified. Accidents happen and mistakes happen. You may knock over a container and it spills out on your friend. What do you do if something is spilled on your skin and burns you? What if you swallow it or breathe in the fumes? What are the emergency procedures, and what should you not do under any circumstances? I ask them who their direct supervisor is; I ask them if everyone has their number. If not, we write it on the wall and make sure everyone has it.”

perforated after rinsing to prevent

reuse, and securely stored.

Discomfort is good

“I spend a lot of time on PPE [personal protective equipment], because many labourers don’t want to wear it since it is so incredibly hot on our farms.”

Based in Mbombela, Charla mainly handles training in the subtropical production areas of Mpumalanga and Limpopo. “We explain to them that the aim of these suits is not to punish or torture them, but to protect them. If they fail to use their PPE, they won’t see the effects now, but one day when they’re old.”

Another point that gets a lot of attention is the hazards associated with the reuse of containers. “A 20-litre container is incredibly useful around the house, so we take time to explain to them that some of the chemicals infiltrate the plastic and is released in the water they store in it, so if you store drinking water in it, you will ingest it in small quantities over a long time. So the message is, ‘Don’t use the containers; it doesn’t help to rinse them three times, and there’s a reason we have to perforate them after rinsing them once the product is finished.’”

Her biggest concern is that many farm workers are far too nonchalant when handling crop protection products. “We always tell them the chemicals aren’t the problem. The car in the garage won’t kill anyone, but the driver driving too fast will. By the same token, the chemistry on its own won’t do anything bad if you use it in the right way. It’s also important to realise that you are the architect of what happens to you if you work with the chemicals – not the product manufacturer and not the owner of the farm. It’s a very human thing to point fingers at someone else, but in actual fact it starts with you. You are the one who has to check whether the filter in your respirator has expired and then tell your supervisor. It’s not their job to check if everyone’s filter works properly. Yes, you may struggle to breathe in your respirator and PPE when it’s 40°C outside. Many guys remove their respirators so they can breathe better; nobody can see it. I tell them you’re not fooling your supervisor or the producer – you’re fooling yourself.”

The agronomists also zoom in on the small details that can make a big difference – like wearing non-absorbent gloves; checking overalls for holes or tears; and avoiding tucking overalls into boots early in the morning when the grass is wet. “What I have found with the farm workers I’ve trained is that when you explain why certain rules are there, it is as if a light goes on for them,” says Charla, who believes this type of training helps to professionalise the workforce. “Instead of experiencing these rules as something forced on them, they start taking more responsibility and realise there’s a risk to their person if they ignore them.”